Ece Nur Retrofit

Another turn-key project delivered by Høglund.

Vessel information:

Built: 2009

Owner: Kaprifol Shipping Ltd

Segment: Chemical Tanker

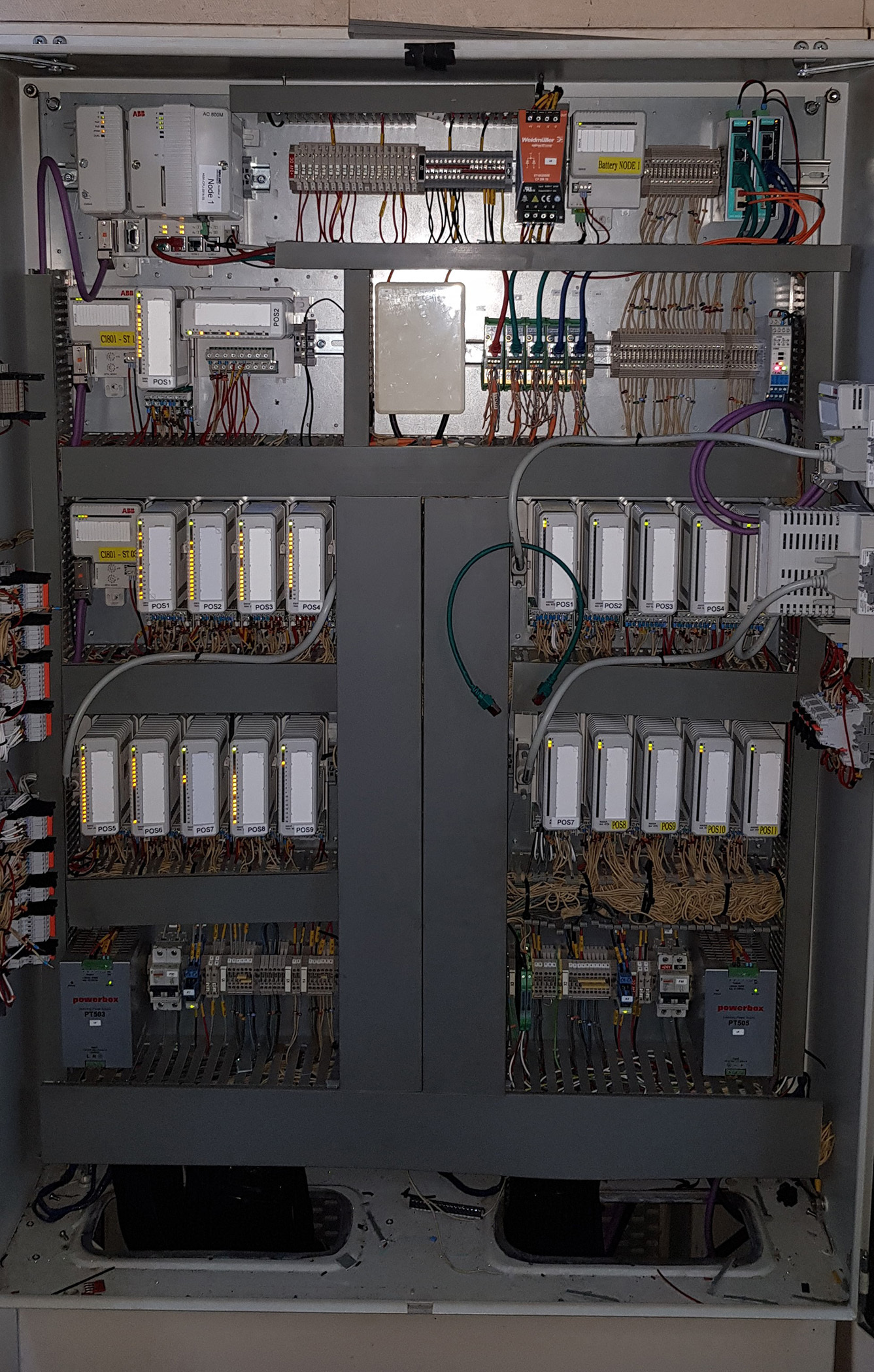

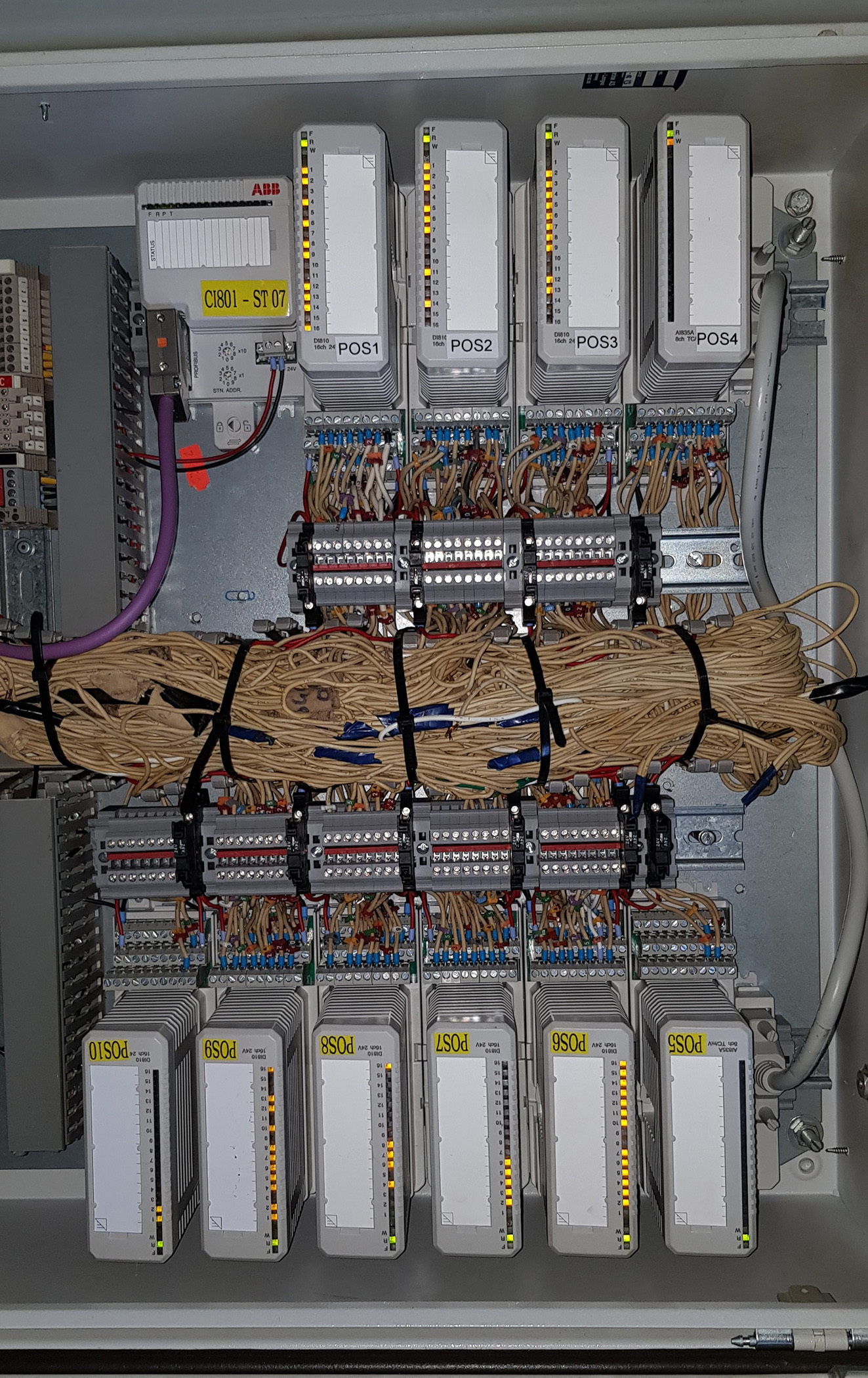

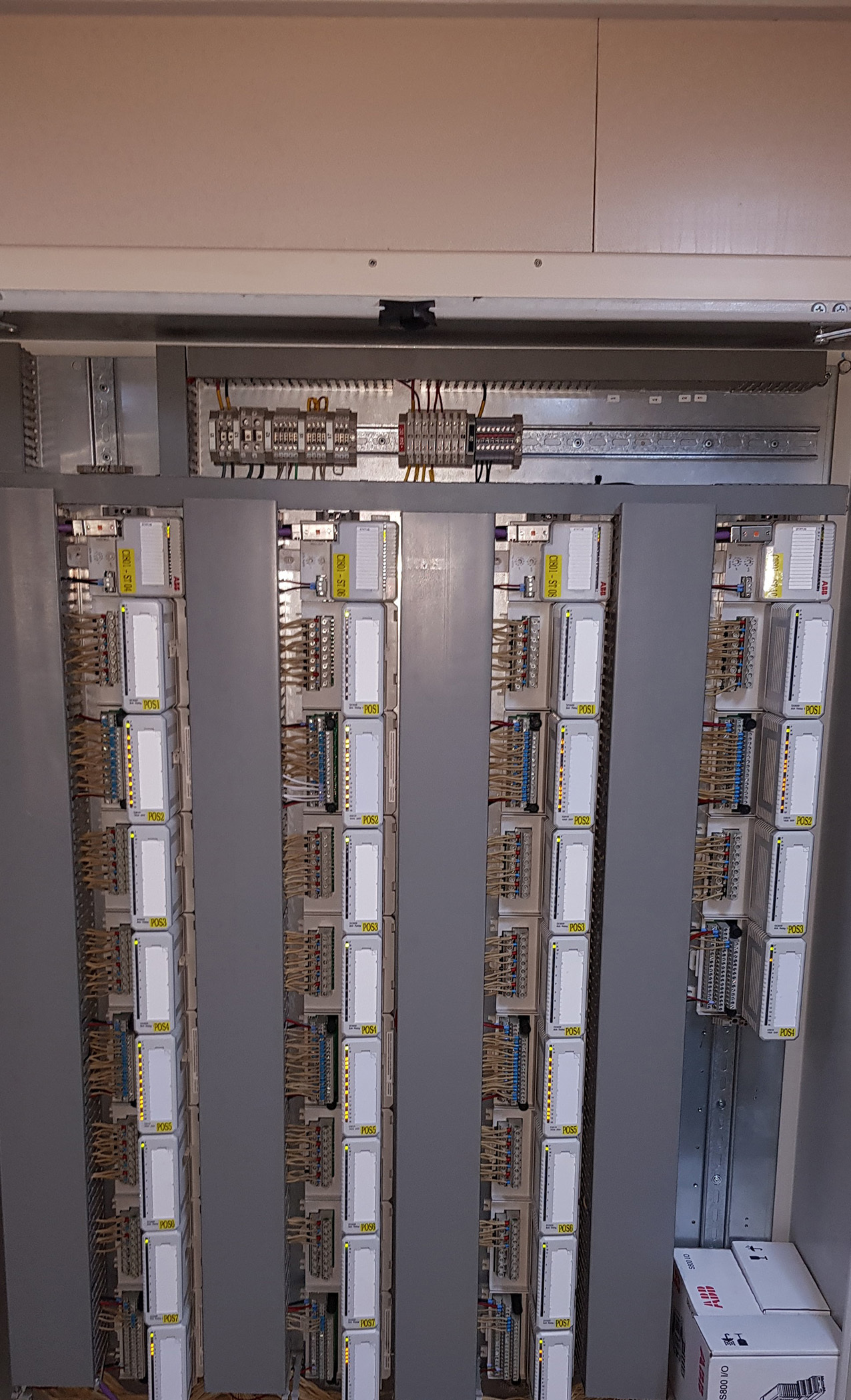

During a 10 days dry-dock period, the 10 year old UMAS system was replaced with a new Høglund Solutions. The system consisted of a cargo control system and engine room alarm and control system. Existing cabinets and field cables were reused.

The biggest challenge for the team of 3 engineers in this project was to fit in some of the cabinets in the new modules delivered by Hoglund, because of the limited space. The team was able to manage this issue, and after 5 days the reconnection of the hardwired signals to the new modules was finished.

The team used 3 more days to test the signals and 1 day to present the system to the class for the approbations and to train the crew to use the new system.

The crew was confident that the system was working properly and that they could use it so there was no need for a Hoglund engineer to attend the vessel for the first trip.

Høglund Solutions Onboard:

- Integrated Automation System (IAS) with Cargo Control

- GMR Playback with 5 month recording of every signal every second

- Høglund Remote Control, for remote service and support

This was a “turn-key” contract, with everything included in the package:

- Approbation with Factory Acceptance Test together with DNV-GL

- Cable Pulling

- Installation, Re-connection and I/O check

- Harbour Acceptance Test with DNV-GL

- Sea Acceptance Test with DNV-GL